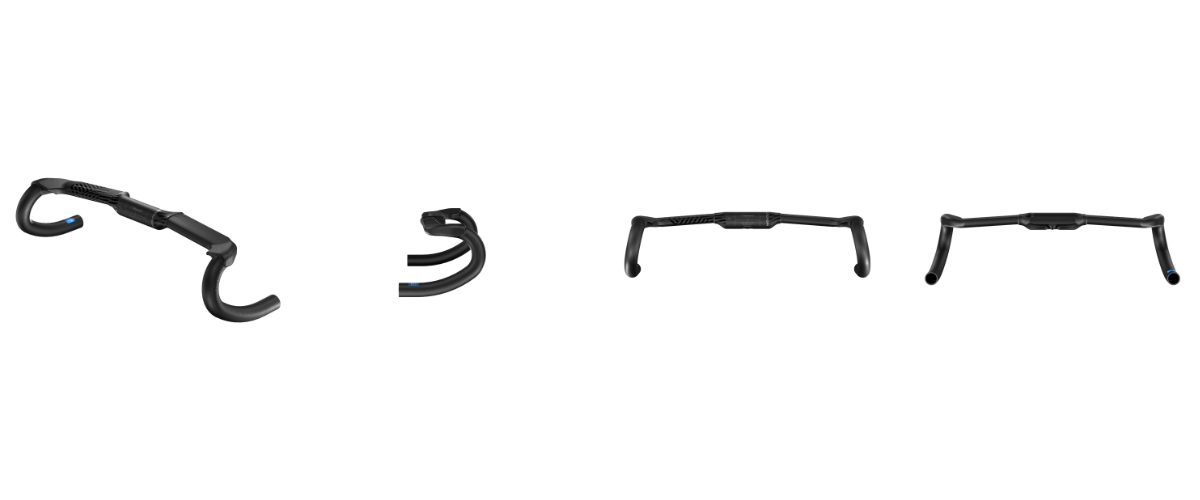

PRO DISCOVER Aero Carbon and the PRO DISCOVER 10 stem to combine aerodynamic gains

Aerodynamic gains in gravel frames, and wheels for all-day riding or fast-paced racing, have become the norm, yet dedicated aerodynamic cockpits have been in short supply.

PRO’s DISCOVER Aero Carbon Handlebar now addresses this need for speed and efficiency, while prioritizing comfort, control, integration, and precise bike fitment. The latter is further enhanced through the addition of the PRO DISCOVER Stem 10 to the brand’s range of dedicated DISCOVER gravel stems.

For gravel racers, explorers or adventurers who demand aerodynamic efficiency the PRO DISCOVER Aero Carbon Handlebar is a full-fledged performance upgrade.

Developed to empower you towards a superior ride, the handlebar features a compact drop with 12 degrees of flare, aerodynamically optimized tops, with a downslope for neutral hand support, and a 4-degree forward sweep to encourage a more aerodynamic body position.

The handlebar’s carbon construction, with strategically placed Dyneema® fibers, offers superb compliance and reduces vibrations, which in turn reduces fatigue on your ride. Control is ensured through the 12-degree flare, while the ergonomic curve to the drops considers shifter and brake integration to ensure ease of shifting and braking across even the roughest of gravel terrain.

The PRO DISCOVER Aero Carbon Handlebar addresses the need of gravel riders to provide a truly aerodynamic cockpit, which is robust enough for the harshest unpaved roads.Mark Kikkert, PRO Bikegear's Product Development Team Manager

"With all PRO components it has been thoroughly tested, both in the laboratory and in real world conditions. The combination of the new aero handlebar’s functionality and aesthetics will help gravel riders not only optimize and personalize their bikes, but empower them with improved real-world efficiency, through aerodynamics and ergonomics.”

The new PRO DISCOVER Aero Carbon Handlebar launches alongside the PRO DISCOVER Stem 10 range.

With a flipable ±10-degree angle, the PRO DISCOVER Stem 10 is constructed from AL 7075 alloy using 3D forging and CNC machining manufacturing techniques and is available in seven lengths from 60 to 120 millimeters (mm), with a standard 31.8 mm clamping diameter. Compared to the existing PRO DISCOVER Stem, featuring a ±6-degree angle, the PRO DISCOVER Stem 10 allows for the perfect bike fit.

“Integrated cockpits might be all the rage right now, but for the vast majority of riders the combination of a handlebar and stem simply allows for a better bike fit, Mark Kikkert confirmed.

“For the PRO DISCOVER range, where comfort and control are our primary aims, it makes sense to provide a diversity of products, and a wide selection of handlebar widths and stem lengths. The PRO DISCOVER Aero Carbon Handlebar is available in 40-, 42- and 44-centimeter-wide versions, while the new PRO DISCOVER Stem 10 adds seven stem length options to the six already provided by the existing PRO DISCOVER Stem.”

Setting the Standard for Gravel

The PRO DISCOVER Aero Carbon Handlebar and the PRO DISCOVER Stem 10 are also the first PRO DISCOVER components to be put to the new PRO Gravel Standard test.

As the first gravel products to be tested under the PRO Gravel Standard protocol, the PRO DISCOVER Aero Carbon Handlebar and PRO DISCOVER Stem 10 are establishing a new standard in gravel safety.

Both electronic and traditional cable actuated shifter cables and hydraulic brake hoses are hidden from the wind in key areas, where they would otherwise cause drag, but are accessible to home and bike store mechanics for servicing. This offering provides the best of both worlds and maintains a sleek, streamlined, look to the PRO DISCOVER Aero cockpit, which will be put to the ultimate test by Laurens ten Dam at Life Time's UNBOUND Gravel, on June 1, 2024, in Emporia, Kansas, USA – the World's premier Gravel event.

“Gravel racing is getting more and more competitive in the last decade,” said PRO Ambassador and elite Gravel Racer, Laurens ten Dam. “I am finally covered to a more aero setup while racing, and I can’t wait to rock these handlebars in the big one, UNBOUND!”

Technical Specifications

PRO DISCOVER Aero Carbon Handlebar

- Constructed from UD T700 carbon with Dyneema® fibers for optimized compliance

- Flare: 12 degrees

- Forward Sweep: 4 degrees

- Drop: Compact 100mm drop

- Reach: 72mm

- Clamping diameter: 31.8mm

- Widths: 40, 42 and 44cm

- Weights: from PRHA0584 – 265g / PRHA0585 – 280g / PRHA0586 – 285

- Compatible with PRO Compact Carbon Clip-On aero extension

PRO DISCOVER Stem 10

- 3D forged and CNC machined AL 7075 alloy construction

- Compatible with electronic shift wires

- Flipable design

- Angle: ±10 degrees

- Steerer diameter: 1 1/8

- Length: 60, 70, 80, 90, 100, 110 and 120mm

- Clamping diameter: 31.8mm

- Weight: from 142g

- Compatible with the PRO Computer Mount

PRO PIONEERS A NEW GRAVEL TESTING STANDARD

From a niche movement, in countries where unpaved roads were plentiful, gravel riding and racing has exploded in recent years. With the discipline booming, distinct sub-categories have emerged within the greater gravel umbrella.

Made up of avid cyclists, PRO’s design, research and product development teams were early adopters of the movement and have now risen to meet the demand for gravel components with the PRO Discover range.

PRO is now, once again, leading the way in this discipline by introducing a gravel testing standard.

Why PRO Developed a New Standard

Quality is in the PRO DNA. Every product is thoroughly tested and exceeds the industry standard. However, there is no general industry standard that gravel components need to pass.

As a result, most gravel components are being tested to a road cycling standard. But at PRO, we believe this is insufficient, because as gravel riding matures it becomes more extreme. As riders take on more technical routes at greater speeds, their equipment needs to cope with the rigors of aggressive gravel riding, so needs to be tested comprehensively to ensure rider safety.

PRO creates components which enable riders to celebrate the liberating joy of sports cycling. Whether they are riding for fitness, mental wellbeing, or chasing sporting goals, riders should not have to think about the strength and durability of their components.

They should be able to trust that regardless of what the adventure of gravel brings, their PRO Handlebars, Stem, Seatpost and Accessories will empower them to focus on the road ahead.

Fatigue Testing PRO Discover Components

Fatigue tests are performed, on most products produced by the cycling industry, to determine the reduction in stiffness and strength of materials under repeated loading. To pass a fatigue test a product needs to reach or exceed a minimum number of load cycles – described as repeated cycling loading – at a particular force, measured in Newtons.

In stage 1 (out-of-phase), the load is applied in opposite directions for 100,000 cycles. This test mimics the repeated left/right loading which riders bring to bear on their handlebars during sprinting or climbing out of the saddle.

For this fatigue test road handlebars are subjected to at least 280 Newtons of force, in an alternating up/down motion for 100,000 cycles. To visualise the test, imagine that the left drop, of the handlebar, is being pressed down while the drop right is raised, and then the right drop is pressed down while the left drop is raised. Each such load constitutes one of the required 100,000 cycles.

In stage 2 (in-phase), the load is applied in the same direction for 100,000 cycles. This mimics the evenly distributed load, between the rider’s left and right hands, during mountain bike riding over rough terrain. During this test the handlebars are subjected to 450 Newtons of force, at both the right and left ends of the handlebars, for 100,000 cycles.

The above video demonstrates how fatigue testing, for a handlebar and stem combination, is performed.

The PRO Gravel Standard Explained

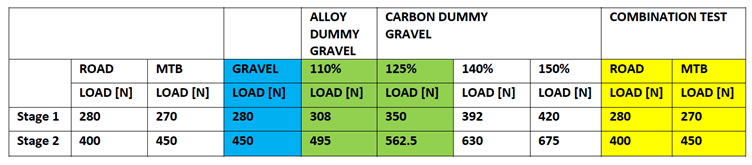

The PRO Gravel standard takes the highest values from Road (stage 1 – 280N) and MTB (stage 2 - 450N) (shown in the table below, listed in blue). The existing PRO Quality Guide describes that for a PRO component to be released to riders it needs to test at 110% load for alloy and 125% load for carbon.

For stage 1, PRO alloy components are tested to 308 Newton, and PRO carbon components are tested to 350 Newton.

For stage 2, PRO components need to pass at the higher MTB force of 495 Newton for alloy, and 562.5 Newtons for carbon. Note the results of stage 1 and 2 for dummy handlebar testing highlighted in green below.

The new PRO DISCOVER Aero Carbon Handlebar is the first PRO DISCOVER product to be tested according to the standard listed above. Its passing should further reassure riders of the robust quality of this new PRO handlebar.

As cockpits are a complete system, PRO also tested the PRO DISCOVER Stem 10 in combination with the PRO DISCOVER Aero Carbon Handlebar This combination test (highlighted above in yellow) was executed to the Road (stage 1) and Mountain Bike (stage 2) standard for complete peace of mind.

Riders who choose the new PRO DISCOVER Aero Carbon Handlebar and PRO DISCOVER Stem 10 can be confident that their riding will be empowered by the best products. Not only from an aesthetic and aerodynamic functionality point of view, but also from the vital standpoint of rider safety.

Available soon.